Products

We provide the best products and solutions

for our customers' goals based on continuous R&D and strategic alliances.

- FABRIC CONVEYOR BELT

- STEEL CORD CONVEYOR BELT

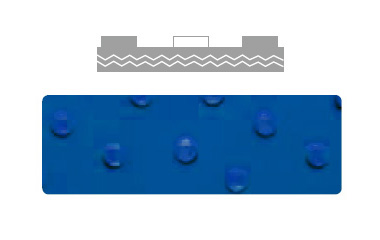

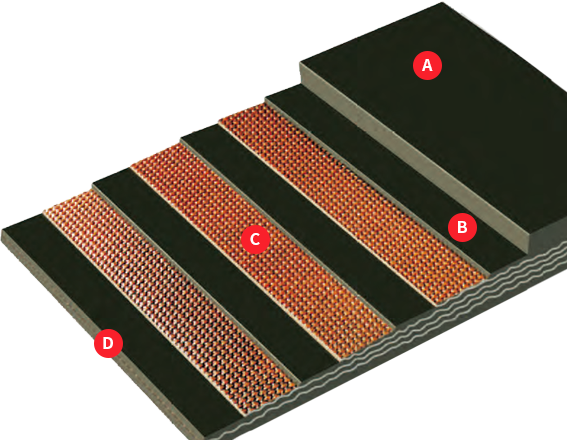

- A.TOP COVER

Desinged to protect the carcass from service conditions like oil, heat, abrasion, etc.

- B.CARCASS

Extremely low stretch characteristics of fabric and good troughability

- C.BOTTOM COVER

Excellent in abrasion and flexibility, provides wearing surface against pulleys and idlers.

- D.SKIM COAT

Compounded for excellent adhesion between plies for protecting against ply separation

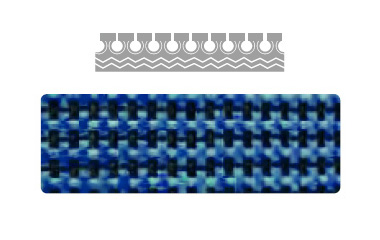

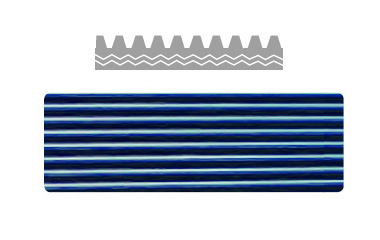

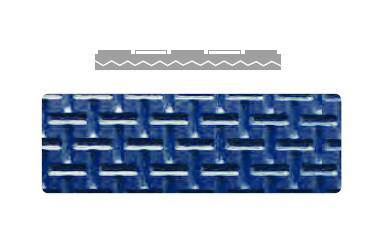

- General/Standard Conveyor Belt

-

Types Usages Sub-types General Conveyor Belt Used general purposely and comprehensively Nylon conveyor belt, EP conveyor belt Standard Conveyor Belt Complies with KS, JIS, ISO, and DIN standard

- Special Conveyor Belt

-

Types Usages Sub-types Heat Resistant C/B Used to carry heated objects and at above 60 degrees Celsius of belt surface temperature. Heat Resistant-100, 130

Heat Resistant-150

Heat Resistant and Flame RetardantOil Resistant C/B Used to carry objects expected to bulge by oil OR-200, OR-300, LOR, MOR Heat/Oil Resistant C/B Applied to a line where heat and oil are accompanied at the same time HTNHot Asphalt Chemical Resistant C/B Used to carry objects to which chemicals are attached Make a proper application of rubber in accordance with the types of chemicals Abrasion Resistant C/B Applied to objects or lines easily subject to abrasion Abrasion resistant, Ultra abrasion resistant Flame Resistant C/B Applied to lines for anti-fire or protection of persons against toxic gases. FR-100,120,140 MSHA, MSHA Grain Colored C/B Used to avoid contamination by cover rubber White colored (general/Heat resistant), Green colored

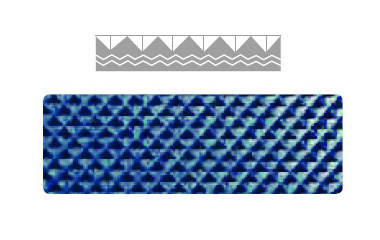

- Special Structure Conveyor Belt

-

Types Usages Incline (Chevron Cleated) C/B For steep slope conveyance Pipe C/Belt For environment improvement in carrying powdery objects Corrugated Sidewall C/B Made up of base belt, cross-fin, and corrugated sidewall for steep slope conveyance. Steel Mesh Belt For mid/long range conveyance Rough Top Belt For conveyance of light and fragile objects packed in sack or cotton box

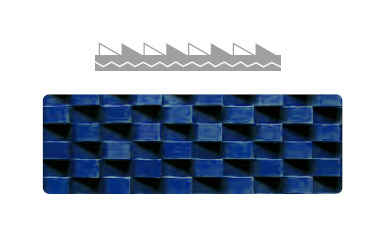

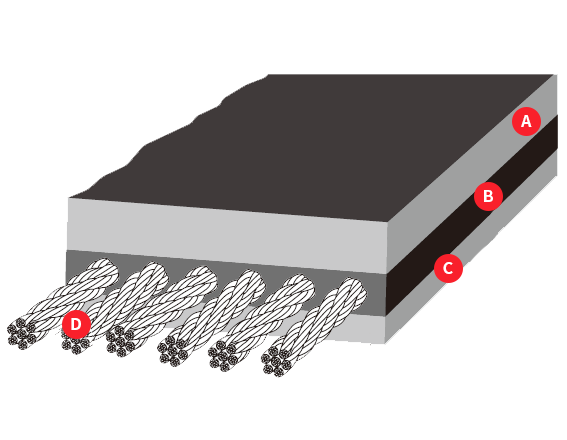

- A.Top Cover

Desinged to protect the carcass from service conditions like oil, heat, abrasion, etc.

- B.Core Rubber

Compounded for excellent adhesion between pliesfor protectinmg against plyseparation.

- C.Bottom Cover

Excellent in abrasion and flexibility, provides wearing surface against pulleys and idlers.

- D.Steel Cord

Extremely low stretche characteristics of fabric and good troughability

- Features of Steel Cord Conveyor Belt

-

- High TensileMade by high carbon steel, Steel Cord Conveyor Belt gives a tensile strength above 6,000 kg/cm2.

- Narrow Pulley DiameterBeing made up of a fine strand, steel cord conveyor belt has excellent flexibility which makes up for its narrower pulley diameter than other general canvas belt's one.

- High Trough AbilitySteel cord belt is 1 ply so that it features excellence in trough ability

- Extremely Small ElongationSteel cord belt is a tenth of general canvas belt in elongation so that steel cord belt minimizes the length of take-up

- Long durabilitySteel cord belt has no extension layer unlike canvas belt, bears the bent fatigue, and adheres closely to rubber, Steel cord belt has excellent resistance to bent fatigue and durability

- X-ray TestAbnormalities of steel carcass can be detected by X-ray so that a damaged part can be repaired partially.

- Performance of Steel Cord Conveyor Belt Material

-

Top Cover

- Tensile strength, Elongation, and Abrasion Resistance.

-

Item JIS-S JIS-G DIN-W DIN-X DIN-Y Tensile strength(Mpa) above 18 above 14 above 18 above 25 above 20 Elongation(%) above 450 above 400 above 400 above 450 above 400 Abrasion Resistance(㎟) below 200 above 150 below 90 below 120 below 150 - Flame RetardationThere are 2 types of standards; MSHA(U.S.A) and FRAS(Australia). FRAS has strict condition.(Test method is in accordance with flame retardation standards).

- Top CoverIt means the distance between the top of steel cord and the surface of a steel cord conveyor belt. It has something to do with the life span of a steel cord conveyor belt.

- Bottom CoverIt should be at least 4 mm thick lest it should cause steel cord to protrude.

- Extremely Small ElongationSteel cord belt is a tenth of general canvas belt in elongation so that steel cord belt minimizes the length of take-up

- Long durabilitySteel cord belt has no extension layer unlike canvas belt, bears the bent fatigue, and adheres closely to rubber, Steel cord belt has excellent resistance to bent fatigue and durability

- UseA. To prevent absorption of water which is subject to temperature difference and may lead to weakening of adhesive strength.

B. For reinforcement of drawing strength of steel cord - TypesClassified into NR or NR+SBR according to a given condition or circumstance.

A. NR: in case of harsh weather condition

B. NR+SBR: in case of moderate weather condition - IngredientsNaphtha Acid Cobalt - for improvement of adhesive strength

Resorcinol - for improvement of adhesive strength

Sulfur

Accelerant (RH)

Carbon ISF in the ratio of 65%~70% - Extremely Small ElongationSteel cord belt is a tenth of general canvas belt in elongation so that steel cord belt minimizes the length of take-up

- Long durabilitySteel cord belt has no extension layer unlike canvas belt, bears the bent fatigue, and adheres closely to rubber, Steel cord belt has excellent resistance to bent fatigue and durability

- MaterialsCord, made of high carbon steel, is used and High carbon steel cord is used and there are three types of steel cord classified according to steel strength; 7X7(6X7+1WS) type and 7X19(6X19+1WS) type.

- Galvanized to prevent it from getting rust by long-term use.

- Cord diameter and pitch are determined by steel strength.

-

Steel Strength Cord Diameter Cord Structure Pitch Steel Strength Cord Diameter Cord Structure Pitch ST-500 2.7 7x7 10 ST-2000 6.0 7x7 12 ST-630 3.0 7x7 10 ST-2500 7.5 7x19 15 ST-800 3.5 7x7 10 ST-3150 8.1 7x19 15 ST-1000 4.0 7x7 12 ST-4000 9.1 7x19 17 ST-1250 4.3 7x7 12 ST-4500 9.7 7x19 17 ST-1600M 5.0 7x7 12 ST-5000 10.9 7x19 17 ST-1800 5.4 7x7 12 ST-6300 12.3 7x19 18

Adhesive Rubber

A special rubber which is bonded with a zinc-galvanized steel cord.

Steel Cord

A special rubber which is bonded with a zinc-galvanized steel cord.

- Quality Characteristic of Steel Cord Conveyor Belt

-

Size Width Total thickness Top Cover Thickness Bottom Cover Thickness Rubber Tensile Strength Cover Elongation S/C Tensile Strengt S/C drawing strength S/C Aging Drawing Strength 1200 × ST1000 ×6×5×300m 1200 ±12 15 ±1.5 6+F/-5% 5+F/-5% above 17Mpa above 400% above 16.5KN/ 1 above 80N/mm above 60N/mm 1198 15.2 7.1 5.0 19.3 610 20.1 118.2 99.9 1200 × ST2500 × 14×6×80m 1200 ±12 26.5 ±2 14+F/-5% 6+F/-5% above 14Mpa above 400% above 39.5KN/ 1 above 130N/mm above 120N/mm 1202 26.7 14.1 6.1 19.2 580 45 145 132